Recommended for companies like this!

- You introduced AGV for the first time, but there is a traffic jam! You want to know how to operate efficiently …

- AGV operating cost is high! You want to reduce the number of AGVs as much as possible …

- You’re considering AGVs from multiple companies, but You don’t know which AGV spec is the best

- You want to evaluate the impact of changing the layout of the factory, such as storage areas, material handling equipment, and flow lines!

- You want to verify the effects of introducing Transit Optimal Platform/xOpt in advance!

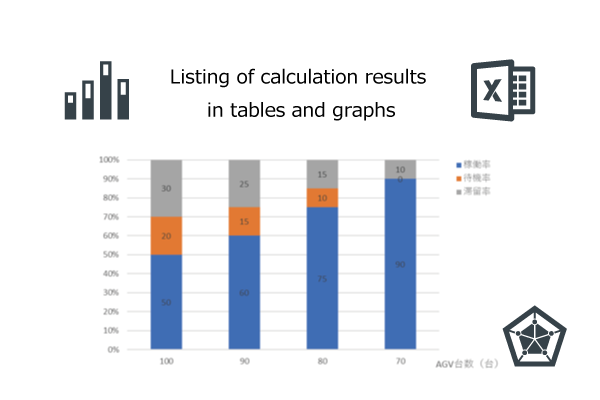

Verification items and evaluation indicators

- We know that each company has a different perspective on logistics issues that they want to focus on.

- LogiUp corresponds to various verification items and evaluation indicators, with the following as an example.

Simulation verification items example

- Material handling equipment route (tracked and non-tracked types)

- Material handling equipment action plan

- Number of material handling equipment units introduced

- Overall layout of factories and warehouses

- Warehouses and automatic warehouse packing rates

Evaluation indicators example

- Eliminate delivery delays

- Energy management of material handling equipment

- Shortest routes

- Standardization of operation of all types of material handling equipment

- Minimization of material handling equipment